Vibration Test Stand | VTS

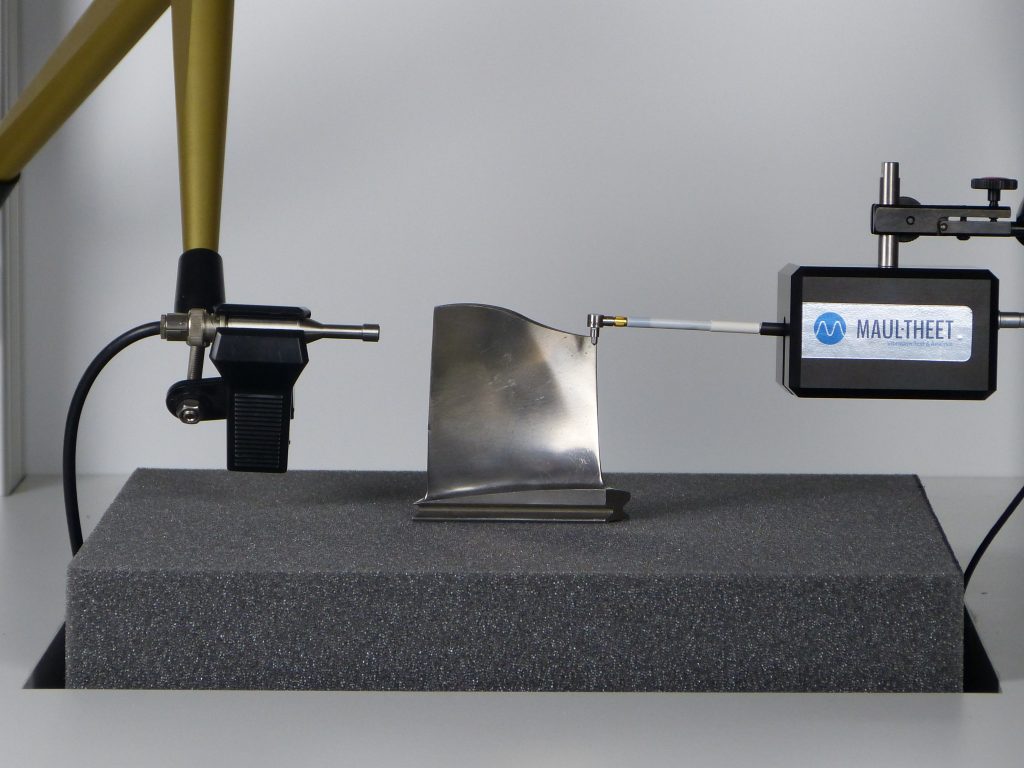

These test stands are developed for high resolution determining of blade resonances. Especially the influence of the clamping of the blades was minimized to guarantee high repeatability.

Advantages & Innovation

Automated test system for determining natural frequencies and damping

Test procedure according to company internal standards

Cost and time savings due to low personnel costs

Scalable for different blade types and sizes

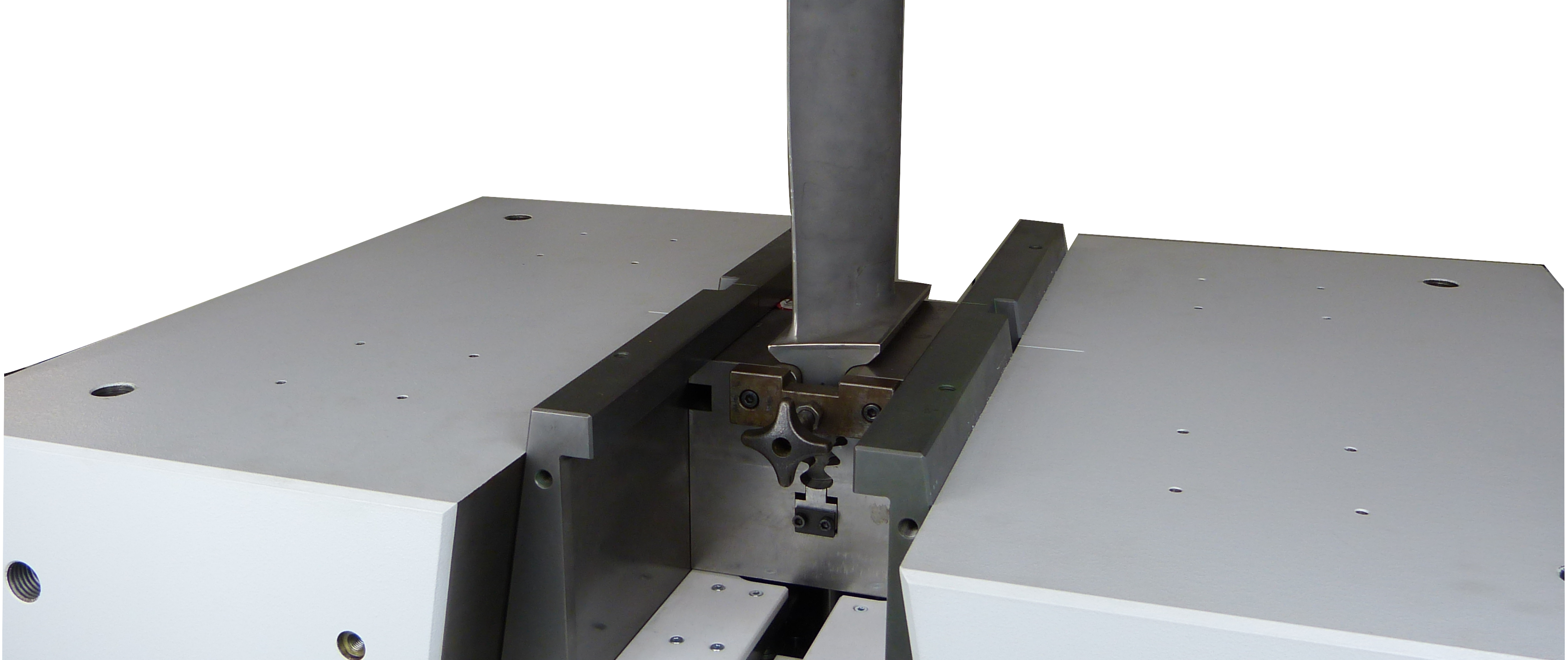

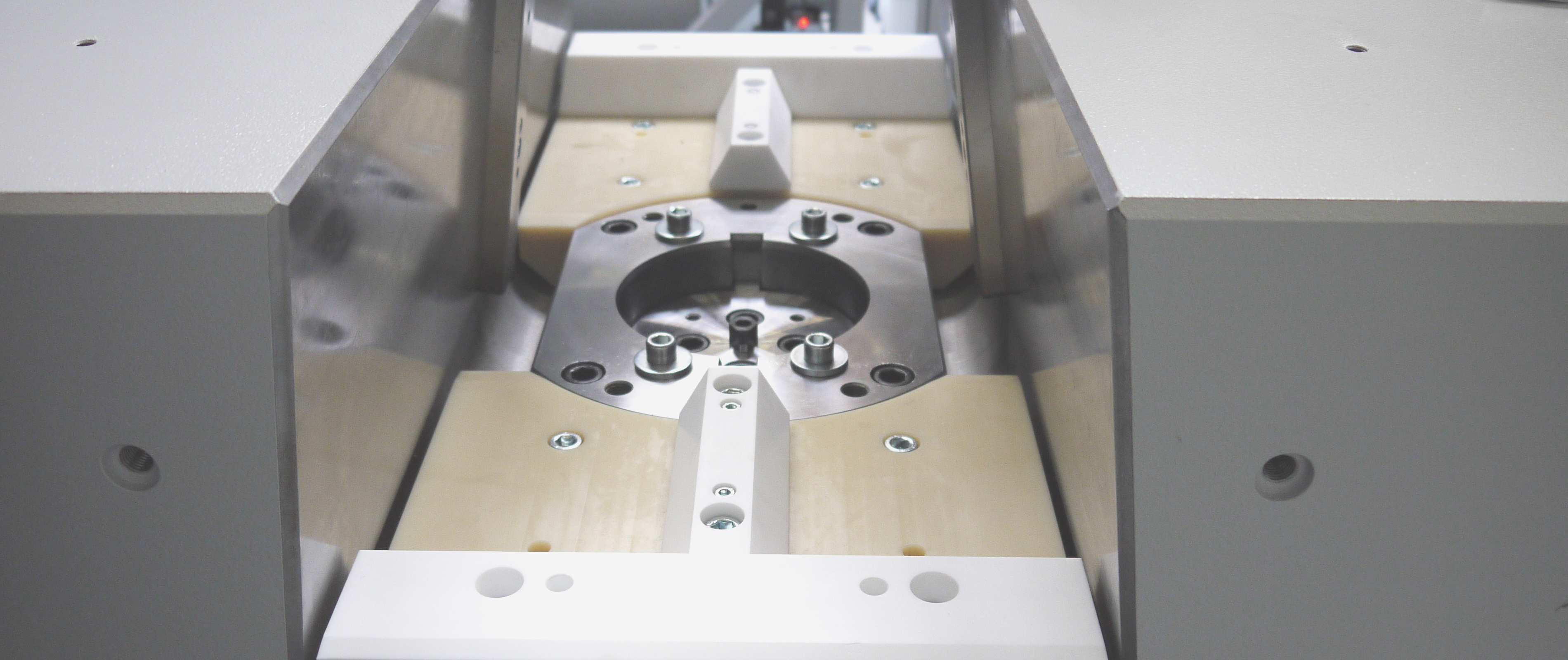

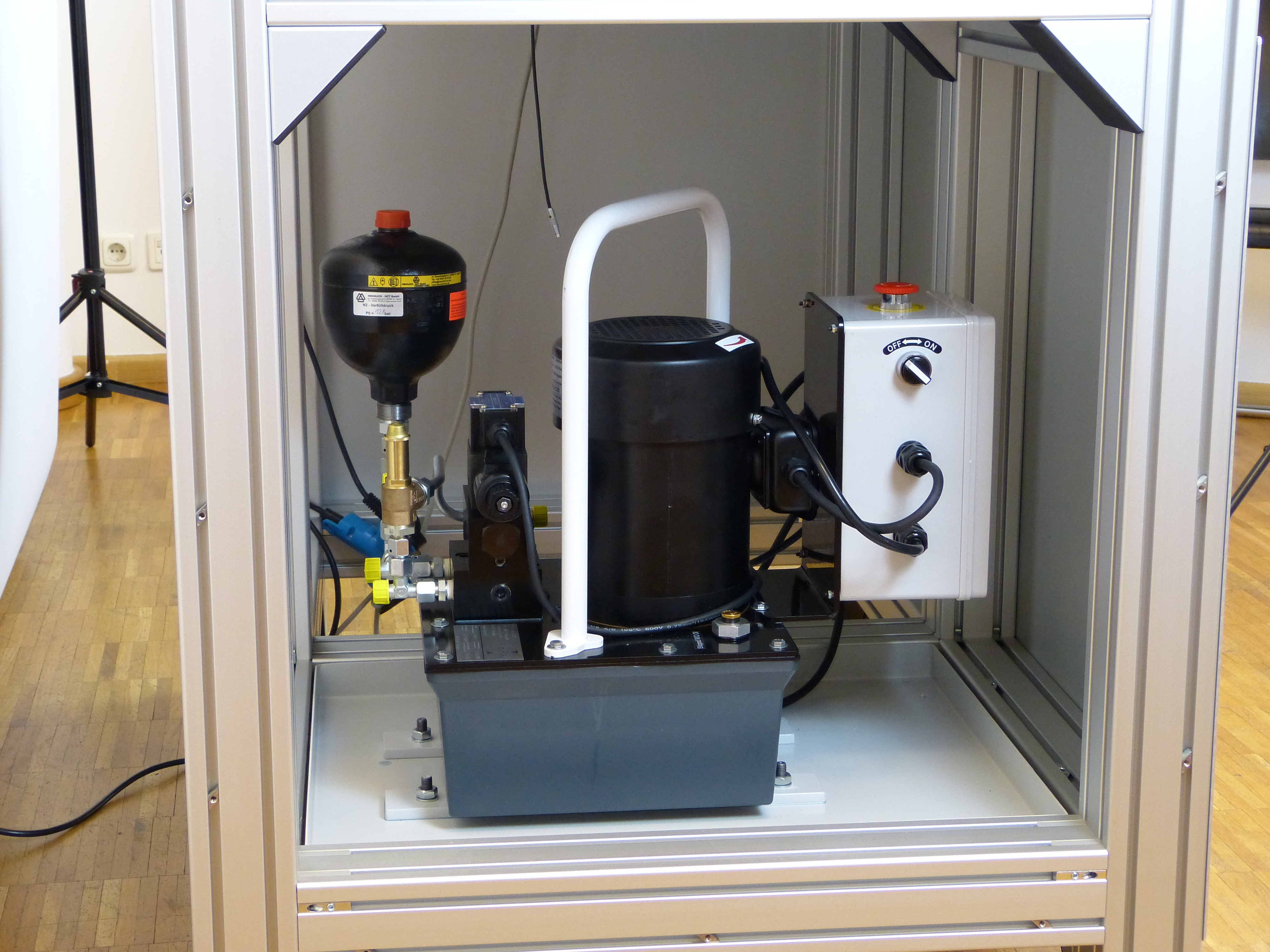

Software-controlled component clamping using hydraulics

Different clamping blocks depending on blade size

Excitation by automatic modal hammer

One click reporting

Blade database

Easy to use

Export to Excel, ASCII or SAP

Vibration measurement with Laser Doppler Vibrometer, accelerometer or microphone

Frequency range up to 100 kHz

Frequency resolution < 1Hz at 20 kHz

Project-oriented database structure

SQL database for multiple workstations

Vibration measurement with Laser Doppler Vibrometer, accelerometer or microphone

Applications & Integrations

Component tests for gas and steam turbines

Component testing of aircraft engines

Turbine blades, compressor blades

Compound material components

blade refurbishment

Quality Control

Series testing

Research and Development

Model updating

Experimental modal analysis

Cost and time reduction

By easing the operation of the software and a high safety level it is possible that normal workers can do the measurements of the test objects. This leads to a reduction of costs and enables the test in the production line. The deviations from the tolerances are detected very early and bad parts can be sorted out. To reach this goal the automation of the following steps was done:

Hydraulic clamping

Automatic resonance determination

Test piece management (Blade database)

With this support a measurement is done with a few mouse clicks.

Measurement

The blade is excitated with an impact hammer and the vibration answer is measured with a microphone or a laser. A high precise data acquisition system ensures the accuracy of the measurement.

Software

The main focus during the development was to create an easy to use and very functional software. The result is a program that can be used for nearly every quality test. The following key features are available:

Sequential measurements (including master blade measurements)

Determining the mode shapes

R&D test measurements

Sequence management

With this support a measurement is done with a few mouse clicks.

Test item management (Blade management)

Analysis & reportsr

User & right management

All setups and measurement data are saved in an local data base, but can also be stored on an main server. The export to Excel or SAP is implemented and with the “Office-Function” it is possible to setup the parameter or define or edit the test sequences form the office PC via the network.

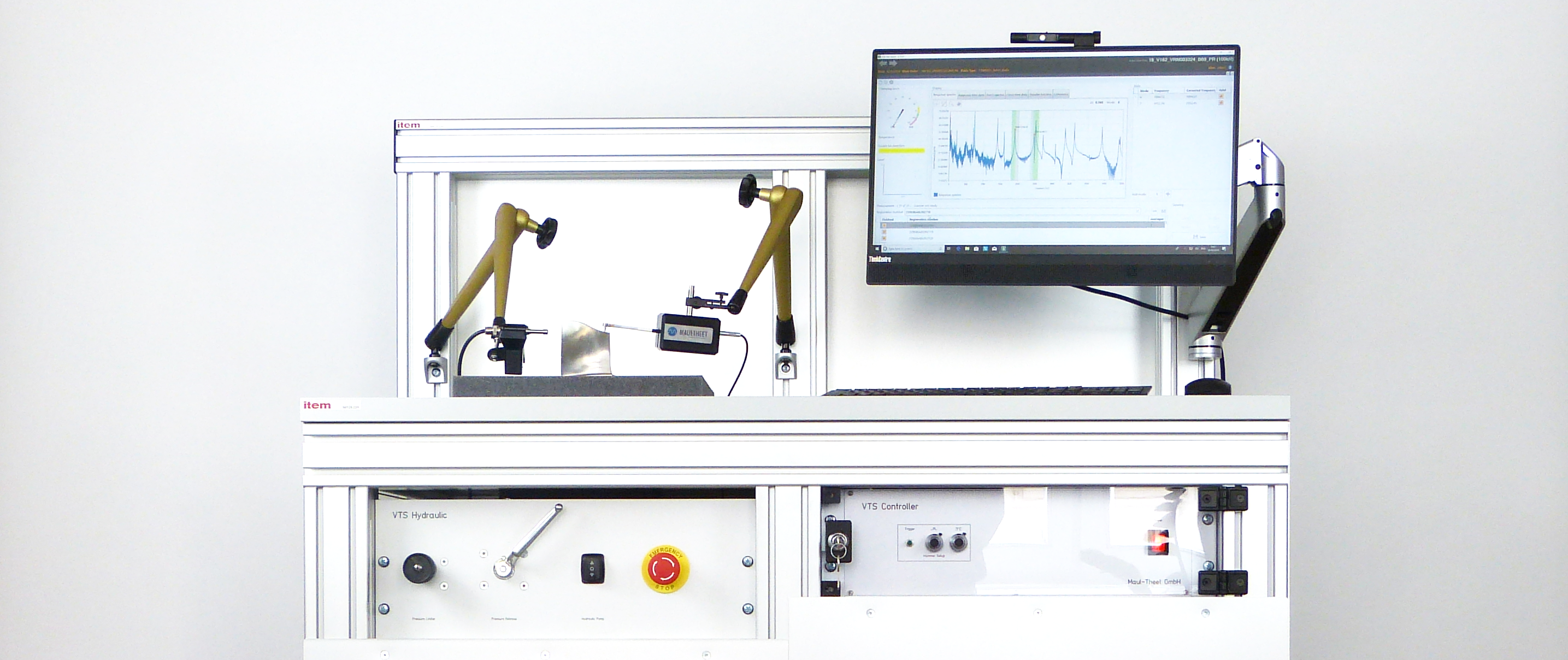

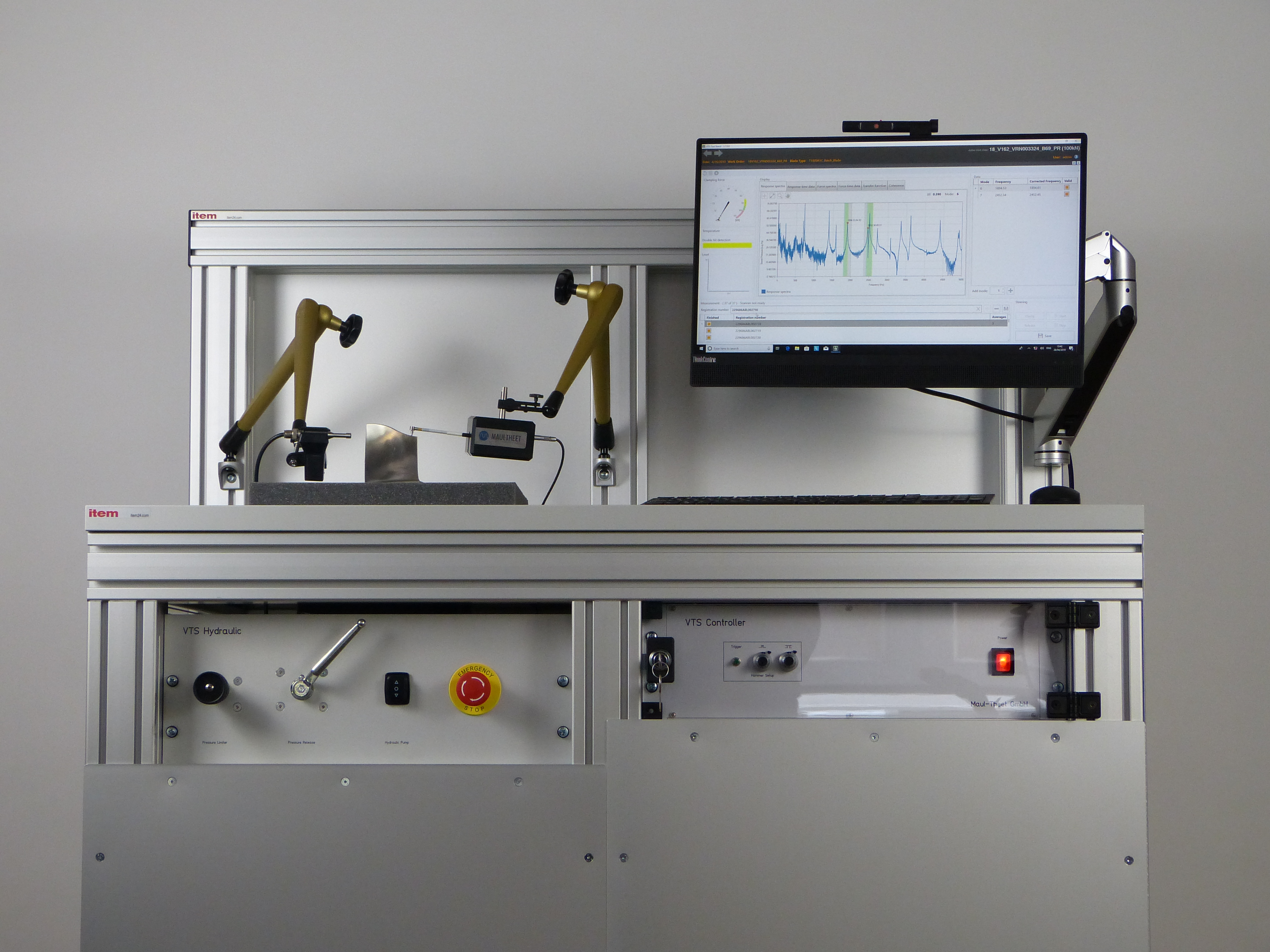

Standard Teststand

Maul-Theet offers three different standard configurations for determining the natural frequencies. In addition, inputs for pressure and temperature measurement are available.

1. VTS with customers own hydraulics

This solution includes all the equipment needed for vibration measurement (modal hammer, sensors, data acquisition) and a PC with software. If the component is clamped in the customer’s own clamping device, an automatic determination of the resonance frequencies can be started. Optionally, a specified clamping force can be checked and documented via a pressure sensor. The results and measurement data can be saved and reports can be created.

2. VTS with manual hydraulics

This solution includes a manually operated hydraulic unit. It is integrated in a test bench made of aluminum profiles, which also houses the clamping unit. The design of the test bench can be adapted to the customer’s application. The clamping force can be adjusted via a toggle switch. It is possible to measure the clamping force with the VTS controller and display it in the VTS software. For clamping forces outside the permissible range, the vibration measurement is automatically blocked by the VTS software.

3. VTS with PLC controlled hydraulics

This solution has a PLC control of the hydraulic unit. The PLC controls the proportional valves to preload, tension and control the clamping force during vibration measurement. The pressure accumulators ensure that the clamping forces remain stable for up to 20 minutes without pump operation during experimental measurements. With PLC-controlled hydraulic clamping forces of up to 650 kN are possible.

VTS test stand configurator

| Teststand | Excitation | Clamping | Vibration Sensor | Monitoring Sensor |

|---|---|---|---|---|

| VTS with customer hydraulics | Hammer without force cell | Customers own clamping | Microphone | Clamping pressure (optional) |

| Hammer with force cell | Laser (LDV) | Temperature (optional) | ||

| Automatic hammer | accelerometer | |||

| VTS with manually hydraulic | Hammer without force cell | Hydraulic manually controlled | Microphone | Clamping pressure included |

| Hammer with force cell | Laser (LDV) | Temperature (optional) | ||

| Automatic hammer | accelerometer | |||

| VTS with PLC controlled hydraulic | Hammer without force cell | Hydraulic controlled by PLC | Microphone | Clamping pressure included |

| Hammer with force cell | Laser (LDV) | Temperature (optional) | ||

| Automatic hammer | accelerometer |